When I began fly fishing many moons ago, popular opinion was that a fly reel for trout was simply a line storage device. I held to this advice for many years, spending my money on reasonable rods, the best fly lines available and affordable die-cast aluminium reels.

It was not until I began slipping and falling on rugged freestone streams that I discovered cheap cast aluminium does not excel in the school of hard knocks. My spools often became warped, jamming against the frame or they simply shattered.

I progressed to machined reels for durability, and it was not long before I came to appreciate the beauty and smooth operation of a high end reel.

My first machined reel, purchased 24 years ago, was a standard small arbour reel. Since then there have been several advances in fly reel design, including: improvements in drag systems, the introduction of injection moulding to improve the strength of die-cast reels and a trend towards increasingly larger arbours.

In this article I discuss the main features to consider when choosing a 5 wt fly reel, primarily for fishing rivers and streams. I don’t include the cassette reels popular with anglers who fish in lakes from boats, using several different fly lines on a given day.

Machined vs die-cast reels

Machined reels are usually manufactured from aircraft grade bar-stock aluminium using CNC technology - Lathes and milling machines controlled by computers; CNC = Computer Numerical Control. Of the many types of aluminium alloy used in the construction of air and space craft, 6061 T6 is most often used for reels as it provides the best trade-off between strength and corrosion resistance. 6061 is an alloy consisting of 95.9% aluminium and small amounts of other elements, e.g. magnesium, silicon, iron, copper and chromium. T6 refers to the type of heat treatment used to harden the alloy.

The machined reels I’ve used over the last 20 years have taken a beating on New Zealand backcountry streams - as outfits frequently get tossed aside when I slip or fall and invariably land, reel first, on boulders. Apart from a myriad dings and battle scars these reels still function perfectly.

Die-cast reels are moulded out of molten aluminium so there’s much less waste in their production; although the aluminium turnings from machined reels are recycled. Nowadays the molten aluminium is injected into the die (mould) and the better ones are finished on CNC machines to create tighter tolerances.

Even though advances in technology and design have significantly increased the strength of die-cast reels, they are not as strong as their machined cousins.

Another disadvantage of die-cast reels is that they are painted rather than anodised, so the coating is not as durable.

Anodising is the process of adding a coloured protective oxide coating to an aluminium surface.

There are three types of anodising according to the thickness of the coating: Type I, Type II and Type III - Type 1 being the thinnest. Most reels are type II anodised, although some reels are Type III anodised, also known as Hard Alox. Most Type III anodised reels are a gun metal colour because it’s difficult to add colours to the thicker coating.

Click and Pawl reels

During the 20th century, the ‘click and pawl’ mechanism was standard on most fly reels for trout. This type of mechanism consists of one or two roughly triangular pieces of metal or pawls that are held against a cog (check wheel) by leaf springs. Although tension on the springs may be adjusted, this is not a drag as such but a mechanism to prevent the reel from overrunning when line is stripped from it.

The drag on click and pawl reels is provided by the angler’s fingers or palm being pressed against an exposed rim on the spool, known as a palming rim, or to the inside of the spool if it does not have a palming rim.

The click and pawl mechanism is responsible for that characteristic sound of classic reels, which may be raucous to some but music to others.

While many companies still produce classic small arbour trout reels with old school click and pawl mechanisms, some have begun producing contemporary large arbour versions.

An old school die-cast full cage click and pawl reel

Drag systems

Drag systems have come a long way over the last two decades. The most common fly reel system nowadays consists of stacked discs, or cones in the case of Lamson reels, made of stainless and synthetic composite materials, such as carbon or teflon, in a waterproof housing.

A waterproof drag is essential as it prevents water and small particles of grit from entering the drag system and causing it to rust or fail.

Drag systems on reels such as the Orvis Hydros and Lamson freshwater reels, are only waterproof as long as the spool is in place. However, these drag systems are not as waterproof as those found on reels where the housing remains waterproof once the spool is removed, e.g. Nautilus or Danielsson.

If a ‘semi waterproof’ reel spends time underwater, a drop of water can get past the O-ring that seals the spool spindle/bush. It’s therefore a good idea to open the housing after the reel has been submersed to allow the clutch bearing to dry, which is easily done on these reels.

Even the seals on ‘fully-sealed’ drag systems will eventually fail if a reel is constantly submerged, and the reel will then require servicing.

Composite drag discs, e.g. carbon or teflon, will also eventually wear out and require replacing.

Some models of reel have complicated drag systems and the reel will need to go back to the manufacturer for repair, e.g. Nautilus NV and Sage Trout. Whereas drag repairs on other models like the Danielsson F3W series can easily be done by the angler.

Galvan fly reels are unusual in that while the drag system is not sealed, the carbon and thermoplastic disc drag system is designed to function perfectly when wet, and there are no metal bearings that can rust. The Galvan reel’s drag system is therefore essentially ‘waterproof’.

Drag Pressure

Drag pressure is the amount of resistance a drag system produces when the line is being pulled from the reel.

When it comes to fly reels for trout, a lot of stopping power is not needed and 2 lbs of drag pressure is usually more than enough. However to protect light tippets the drag needs to be smooth with no initial inertia.

Even though my trout reels have powerful drags, I like to set my drags so they are just strong enough to prevent overruns and I prefer to use the palming ring on the spool to control the fish. Not only do I prefer the feel of controlling the fish with my fingers, but it’s also easier for me to strip line from the reel before casting.

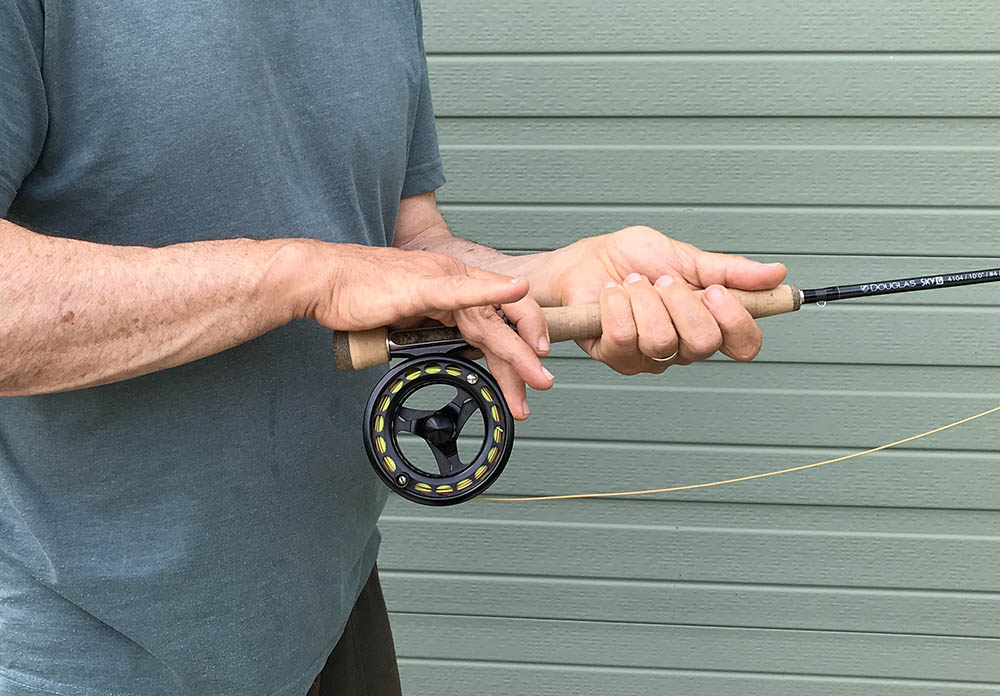

Applying my middle finger to the palming ring on top of the spool while wrapping my thumb around the rod butt, gives me the greatest control of both the spool and rod (see photo). This method works equally well on both click and pawl reels and reels with drags, as long as they have an exposed spool with a palming rim.

Hand position of ‘palming’ the spool which gives me great control of both rod and reel

Arbour size

The arbour is the central hub of the reel to which backing is attached.

While classic trout reels have standard or small arbours, there’s been a trend since the 21st century toward increasingly larger arbours.

Small arbour, large arbour and Uber large arbour 5wt reels.

Note how reel diameter increases with arbour size.

Advantages of large arbour reels are:

| 1. | Higher retrieve rate - there’s a noticeable difference between the retrieve rates of my 3.5 and 3.75 inch large arbour reels, the latter being faster.

|

| 2. | Less coiling of mono running lines and fly lines.

|

| 3. | Slower rotation when fish are running.

|

| 4. | The reel doesn’t speed up, increasing drag, when line is peeling off the reel and effective arbour size diminishes. |

Large arbour reels generally have larger overall diameters and wider spools to maintain the same line capacity or volume as a small arbour reel.

5wt large arbour reels are therefore heavier than small arbour 5wt reels, but are usually not too heavy to balance modern graphite rods 9 ft or longer.

A disadvantage with very wide shallow spools on some large arbour reels, is that the line needs to be guided onto the reel to prevent it stacking up on one side and jamming against the frame.

Some anglers maintain that the larger the reel+arbour diameter the better, but there’s often a tradeoff between functionality and aesthetics - beauty being in the eye of the beholder.

Personally, I find that reels with a diameter much greater than 3.5 inches don’t look good on 9 ft 5wt rods, especially when photographed with fish. I also like my rod to rest on the rod butt when leaning against a fence, car, rock or tree, and not on the reel.

I am happy to go up to a reel diameter of 3.7 inches on a 9.5 or 10 ft rod, especially if it has a fighting butt which I prefer on longer rods - but this is clearly a personal preference.

It’s possible to enjoy many of the advantages of a large arbour reel when using a classic small arbour reel, by using a reel that’s one or two line sizes larger and filling it up with backing, e.g. a 3.5 inch #7 Hardy Marquis LWT for a 9 ft 5wt rod.

Additional backing of course adds weight, but because small arbour reels are often very light this extra weight is usually required to balance a 9 ft or longer rod. The Hardy Marquis #7 only weighs 4.6 ounces when empty of line.

Weight and balance

A recent experiment I conducted shows the importance of reel weight and balance for 9 - 9.5 ft fly rods.

Reels that were too light made the rod feel ‘tip heavy’ with a high swing weight and produced tails on long casts. Reels that were too heavy, on the other hand, slowed the casting stroke and dampened the feel as they produced noticeable inertia.

Based on my grip, ie. thumb on top of the cork, I found that the ideal reel weights, with backing and fly line attached, were 6 - 6.5 ounces for a modern 9 ft 5wt graphite rod and around 7 - 7.5 ounces for a 9.5 ft 5wt. Without the fly line and backing the ideal reel weights were 4.8 - 5.2 and 5.5 - 6.0 ounces, respectively.

To find out more see ‘Balancing a fly rod' link at end of article.

Backing Capacity

A 5wt reel for large trout like those found in New Zealand, should hold 75 to 100 m of backing,

While I’ve never used more than about 50 m of backing when fighting a fish, on some occasions I had to follow a fish for at least a 100 metresdown river. I’ve also heard reliable reports of anglers using almost all their 100 m of backing on large fish hooked on lake shores - fish that would not have been landed with 50 m of backing.

Many reels do not take as much 20 lb Dacron backing as the manufacturer states. In cases where reels will not fit more than 50 m of 20 lb Dacron, it’s possible to increase backing capacity by using a 50 lb 8-carrier PE braid. PE braid is also more durable.

For more about using PE braid for backing, see link at end of article.

Full cage vs reduced cage

Originally, all fly reels had full cages because full-caged reels were more robust. Cages were later cut back to reduce weight made possible by developments in technology, including CNC machining. Even though reduced cage reels are now the most common, they may not always be the best option.

Reduced cage and full cage large arbour reels with sealed drags

Full cage reels have the following advantages over reduced cage reels :

| 1. | Being slightly heavier, full cage reels provide better balance for longer rods.

|

| 2. | They are more robust - although I’ve never managed to destroy a high-end machined reduced cage 5wt reel.

|

| 3. | They prevent mono running lines and thin euro-nymphing lines from squeezing between the spool and a reduced frame - known as ‘pull through’. |

Spin

Some reels with drags have so little retrieval resistance that they spin if you slap the palming rim or flick the handle. The drag prevents them from spinning in the reverse direction. A spool that spins in the retrieval direction is particularly useful for quickly getting rid of loose mono running line when stripping streamers once a fish is hooked. I also use this feature with regular fly lines whenever I hook a big fish.

Loose line shooting about when a big fish takes off is likely to tangle on your gear - and end in tears.

Sound

Click-and-pawl reels have a characteristic loud sound.

Modern drag reels range from completely silent to a sound that rivals any click and pawl.

Some anglers like noisy reels, while most seem to favour a moderate sound, and the rest prefer silent reels. If sound is important, make sure to check that out before making an online purchase.

Conclusions

My recommendation for a 9 ft 5wt rod would be a machined aluminium reel with a diameter of 3.4 - 3.6 inches that weighs 6 - 6.5 ounces loaded with at least 75 m of backing and a full floating 5wt fly line.

Large arbour reels ideally need to weigh 4.8 - 5.3 ounces without any backing or fly line. Small arbour reels of this diameter would need to be around 4.5 ounces as they would require around 200m of backing to fill them.

If the reel has a drag it should be waterproof and smooth, and - whether it has a drag or not - an exposed spool or palming rim is essential. Drags that can be repaired by the angler are also an advantage.

When it comes to 9.5 or 10 ft rods my preference is a reel diameter of 3.5 - 3.75 inches with a weight of 5.5 to 6 ounces, capable of holding 100 yards of backing and a 5wt line.

If reels are to be used for Euro nymphing, jig streamers and mono rigs, or Spey casting with thin mono running lines, then a full cage design is a good idea. A reel with low retrieval resistance is also useful for these fishing applications.

The Danielsson F3W series have full cages and they spin incredibly well.

Good luck with choosing your next 5wt fly reel.

Also see :

See gear reviews :