Backing may be the last part of your gear you spend time or money on but when you hook that trophy fish, the type and amount of backing on your reel makes all the difference between ‘grip and grin’ or ‘grit and grimace’.

The main purpose of backing is to provide enough line to fight those fish that run further than the length of the fly line, but it’s also sometimes used to fill reels to increase the effective arbour size and retrieve rate.

The amount of backing required depends on the size of the fish and how far they’re expected to run.

100 m is usually more than enough for trout, 200 m is about right for bonefish and smaller saltwater predators, and 300 m is recommended for tackling ocean speedsters such as large Pacific bonefish, tuna, permit, Spanish mackerel and queenfish.

Types of Backing

The ideal line for backing should have a good strength to diameter ratio, little stretch and be rot resistant.

Two types of backing are commonly used on fly reels: Dacron/micron, the old standard, and PE braid, a relatively new comer.

Dacron is a brand name for a braided line made from polyethylene terephthalate (polyester), which is a thermoplastic polymer with little stretch. It’s usually available in 20 lb and 30 lb breaking strain, and diameter for each of these two breaking strains can vary quite a bit between manufacturers.

Gelspun, PE and Spectra braid all refer to the same product: a braided line created from high-modulus polyethylene (HMPE). HMPE has extremely long chains and consequently a very high breaking strain to diameter ratio and also no stretch.

Spectra, Dyneema and Izanas are brand names for the raw PE fibres made in different factories, which are then woven into braided lines by fishing line manufacturers. The number of fibre bundles woven together to produce a braided line is referred to by several terms including: #-carrier, #-ply or simply #x - where # is the number of bundles.

When fishermen refer to ‘braid’ they are usually referring to the HMPE variety, rather than braided Dacron or braided nylon.

Advantages of using PE braid for backing are:

1) it is much thinner than Dacron for a given breaking strain, so one can fit more on a reel,

2) it is more resistant to the elements, including UV, so lasts much longer, and

3) the individual fibres do not absorb water, so its dries quicker.

I began using braid about 15 years ago, so I could fit 100 m of backing on a new 5/6wt trout reel that had an optimistic advertised backing capacity; which is not unusual. I also found I could squeeze 150 m of the same 50 lb Berkley braid onto a 7/8 salt water reel with a 9wt line.

Four-carrier braid (or four-ply or 4X) was the standard in those days, and being very thin and rough to the touch it has a reputation for cutting fingers on long fast runs. Fortunately the thousands of kahawai and trout I’ve caught never ran much more than about 30 m into the backing, and finger damage was never an issue.

Eight Carrier Braid

A few years after my initial foray into using braid for backing, Hatch Outdoors came out with a 68lb eight-carrier PE braid backing much smoother than the original four-carrier and had a diameter of 0.37 mm, which is significantly thinner than 20 lb Dacron. It is advertised as having the feel of Dacron with the strength and durability of braid, all of which is true.

I filled a Nautilus NV-G 8/9 reel with 200m of Hatch braid for a visit to Aitutaki in 2011, where it was put through its paces with large bonefish and some good trevally. My index finger appreciated the smooth texture of the eight carrier braid when frantically guiding backing onto the reel after 100m plus runs. If you don’t do this properly with a thin line, it could dig into itself when you put the pressure on.

On one occasion an 8 kg bluefin trevally wove the fly line and backing through a couple of coral bommies as it tore out to sea across the reef. After freeing the line and backing I had to drag the fish up through a gut against a dropping tide. This strained my 9wt rod to breaking point and even though the fly line was scuffed in several places, and the hook partially straightened, the backing held. The fishing guide had provided me with 100 lb fluorocarbon leader/tippet - he knew what to expect.

These days all brands of PE braid are marketing at least one 8-carrier PE braid range. A few years back all my freshwater reels were filled with 50 lb Shimano Kairiki - before the release of Siglon ADV.

My wholesale move to an affordable 8-carrier braid was not only for backing capacity but also durability. When I tested all the 20 lb and 30 lb Dacron I had on my fly reels for 10 years, they popped easily at the surgeons-loop knot, which put me off Dacron completely.

When it comes to solid braid - versus hollow core braid, which I discuss later in this article - 8-carrier braid provides the best trade-off between smoothness and abrasion resistance. 12 carrier braids are produced by many companies but are not as abrasion resistant as their 8-carrier counterparts. Eight-carrier braid being much smoother than 4-carrier braid and as smooth or even smoother than Dacron.

Selecting braid for backing

Most fly-line companies are marketing solid braid backing, however just because solid braid is marketed as backing doesn’t mean it’s the best product for this purpose.

Many years ago Scientific Anglers came out with 30 lb and 50 lb XTS Gel Spun backing, a 4x braid that's rough to the touch and still available.

Rio came out with a 50 lb PE braid that was recently upgraded to a 65 lb 8X version, although they don’t specify diameter. The carrier count of Cortland solid braid varies with breaking strain, starting with 4x for 30 lb, increasing to 6x for 50 lb, and finally to 8x for 80 lb.

Diameter is the primary consideration when selecting braid for backing, because diameter determines handleability, abrasion resistance and reel capacity.

Thinner lines provide more backing capacity and less drag in the water. But going too thin makes them difficult to handle with fast running fish and increases the risk of break-off due to reduced abrasion resistance. Thin lines also tend to dig into themselves on fly reels.

The ideal trade-off of diameter and breaking strain depends on what fishing situation you’re using it for.

After experimenting with many different braids for fly line backing and slow jigging, my recommendations for 8-carrier braid as fly-line backing is to go with a diameter of 0.34 - 0.37 mm for trout and 0.37-0.40 mm for saltwater 7-10 wt outfits and Spey applications; if it’s important to increase backing capacity.

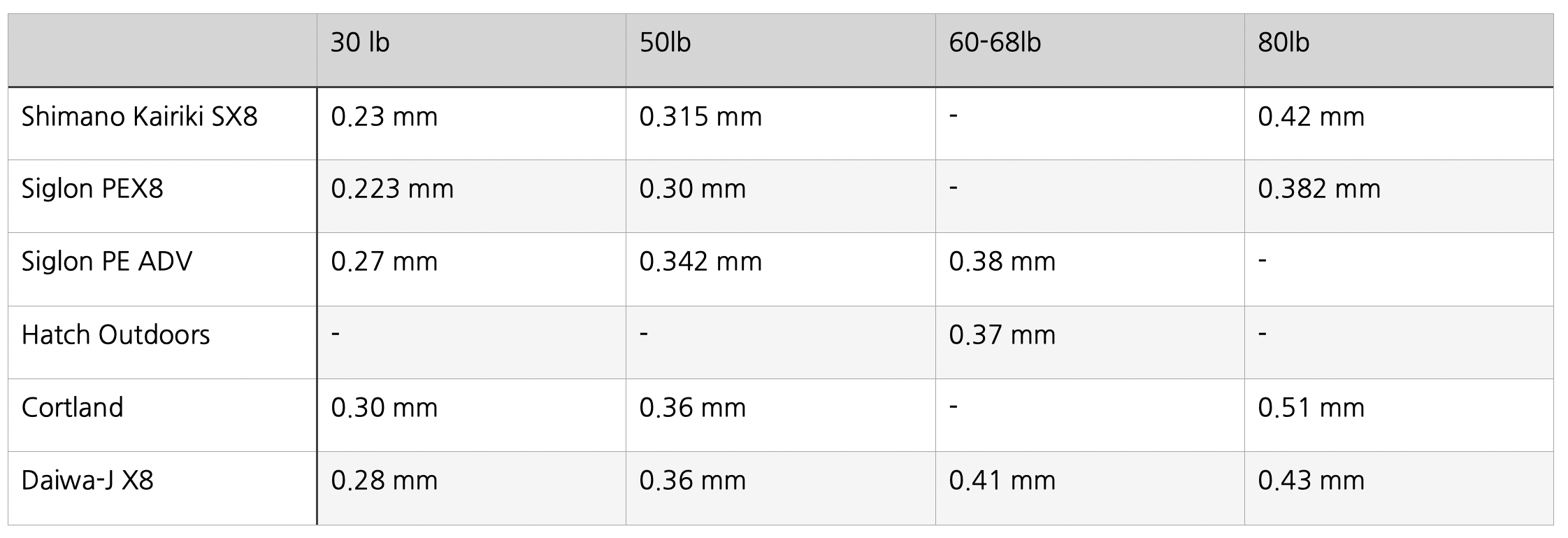

The table below shows the advertised diameters and breaking strains of Shimano, Siglon and Hatch Outdoor 8-carrier PE braids which I have had extensive experience with. Also provided are the advertised dimensions of Cortland solid braid backing that increases in carrier count with breaking strain, from 4x to 6x and then to 8x.

Measuring the diameter of 8-carrier braid is notoriously difficult because it's rectangular in cross section and advertised diameters are not always accurate.

For example, I cannot tell the difference in feel or backing capacity between ‘0.315’ mm 50 lb Kairiki and ‘0.37’ mm 68 lb Hatch outdoors, or '0.38, mm 60 lb Siglon ADV. The ‘0.34’ mm 50 lb Siglon ADV is noticeably thinner than the ‘0.315’ mm 50 lb Kairiki. It therefore seems the Kairiki advertised diameters are underestimated.

When trying to squeeze as many meters as possible onto a reel, verifying advertised diameters can make a big difference.

Breaking Strain

Breaking strain is not usually a major consideration when choosing braid for backing as the appropriate diameters are more than strong enough.

Going with a higher breaking strain will compensate for the significant loss in tensile strength if knots are used to join backing or create loops. See ‘Making end loops in 8-carrier braid’ further in this article.

Breaking strain is reported differently for different brands and even for models within brands. For example, the breaking strain stated for Siglon PEX8 is the maximum breaking strain recorded from a series of tests.

The breaking strain for Siglon ADV, on the other hand, is the average breaking strain mentioned on the box - the maximum breaking strain is also provided on the box but in small print. Sixty pound Siglon ADV, with a maximum breaking strain of 80 lb is essentially the same line as 80 lb PEX8, but with a different coating. They both have a diameter of 0.38 mm.

To complicate matters further, independent tests revealed that many braids, including Siglon PE ADV, consistently break at loads well above the listed average breaking strain, while others break close to or well below the stated breaking strain.

The moral of this story is that if breaking strain is important then one needs to know how it’s calculated for each of the brands under consideration. Tests by independent unbiased reviews published on the internet are particularly useful in this regard.

Coating

Although 8-carrier braids from different brands are woven from the same material, the tightness of the weave, the resin coatings and colours used create a range of stiffness and slickness. While stiffer, slicker braid is better for casting on conventional reels it doesn’t necessarily make much difference for fly line backing, especially in diameters suitable for this purpose. Hatch Outdoors braid backing, the original 8X PE backing, has no coating at all.

There are some coatings that have advantages for backing, like those designed to penetrate between the fibres of each strand and repel water, as well as increase abrasion resistance, e.g. Siglon ADV. This coating’s purpose is to keep water from penetrating the bundles of fibres so the line remains lighter and casts further.

While casting further is not an advantage for fly line backing, a fly reel with 300 m of Siglon ADV as backing would pick up less weight when dunked and also absorb less salt. Improved abrasion resistance and knot strength clearly also have benefits for backing.

Making end loops in 8 carrier braid

Most anglers create end loops in their backing to attach to the welded loop in the rear end of the fly line. It’s easiest to attach or remove fly lines if the backing loop is large enough for the reel or for the spooled fly line to pass through it.

Knots commonly used to create loops in PE braid are a 4-6 turn Surgeons Loop, the Spider Hitch and the Bimini Twist.

What many anglers do not realise is that, as with Dacron, tying a knot in braid will reduce its breaking strain by as much as 40%.

While the Bimini Twist returns 100% of the breaking strain in nylon or fluorocarbon, in the case of PE braid that does not stretch, this knot does not perform as well. It’s also a relatively large clunky knot and difficult to tie consistently in braid.

Many anglers use a five turn Surgeons Loop, which is quick and easy to tie consistently with braid, and tightens down to a very small neat knot.

For those who enjoy the reassurance of a loop that does not compromise the strength of their backing, or to avoid knots slipping or weakening over time, or like a perfectly smooth connection without knots that might catch on things, there’s the Stitch Splice, which I highly recommend and it is easy to do. (I provide a PDF link for method at end of this article).

Once a loop is created in the backing it’s attached to the welded loop in the fly line using a loop-to-loop connection. As PE braid used for backing is so thin, there’s the danger it could cut into the coating of the fly line loop on heavier outfits when handling large powerful fish.

Two methods are commonly used to avoid this:

| 1. | The simplest involves pushing the backing loop through the loop in the fly line then passing the fly line (usually on a spool) twice through the loop. If done properly you end up with a cross of braid on one side of the fly line loop and four strands of braid in contact with the coating of the fly line.

Two passes of the spooled fly line through the backing loop, produce a cross on one side of of the fly line loop and four strands of braid in contact with the coating

|

2. |

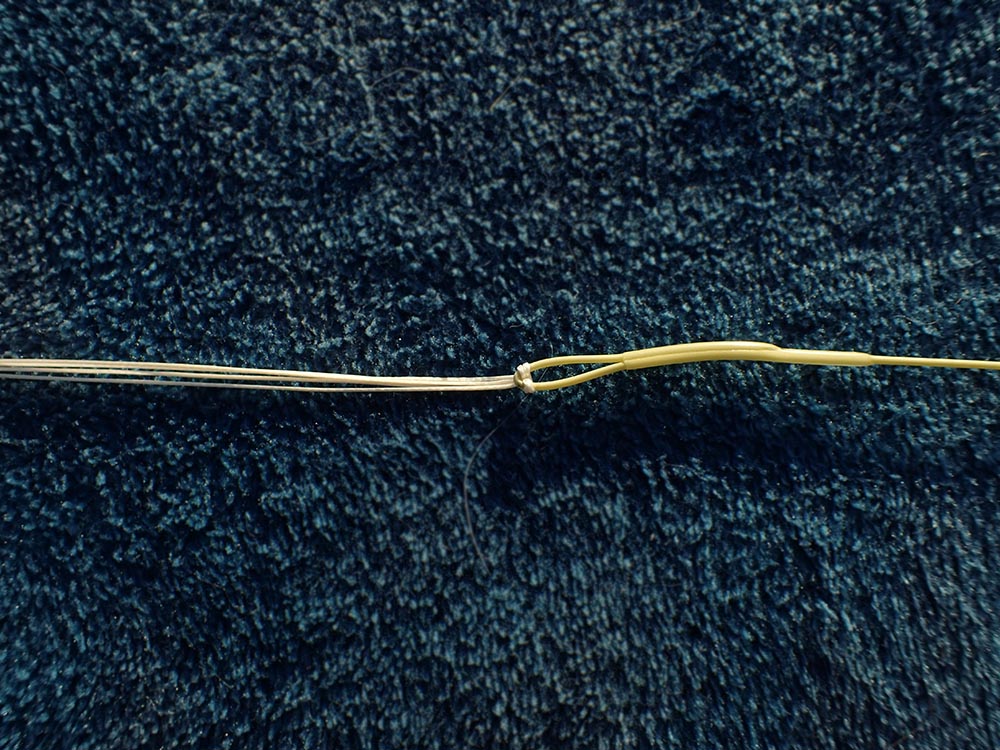

First create a larger loop in the backing of around 2.5 ft long. This loop is then doubled over and a two-turn Surgeons Loop tied close to the initial loop knot (or splice) to create two loops of even length. The twin loops are then poked through the fly line loop and the reel passed once through both loops.

This method also results in four strands of braid in contact with the fly line loop, which spreads the load more evenly than the first method above. This seems to be the preferred method for saltwater anglers targeting large gamefish. As the Surgeon’s Knot is tied in four strands of braid it’s very strong. The weakest point in this connection is the knot creating the initial loop, but if you use a Stitch Splice there will be no weak point.

A twin loop connection created with an initial Spiders Hitch and then a two turn surgeons knot. The Spiders Hitch could be replaced with a Stitch Splice

Twin loop system attached to fly line |

The Stitch Splice

The Stitch Splice works well on braid with diameter >0.30 mm, and, unlike a knot, doesn’t compromise the strength of the braid.

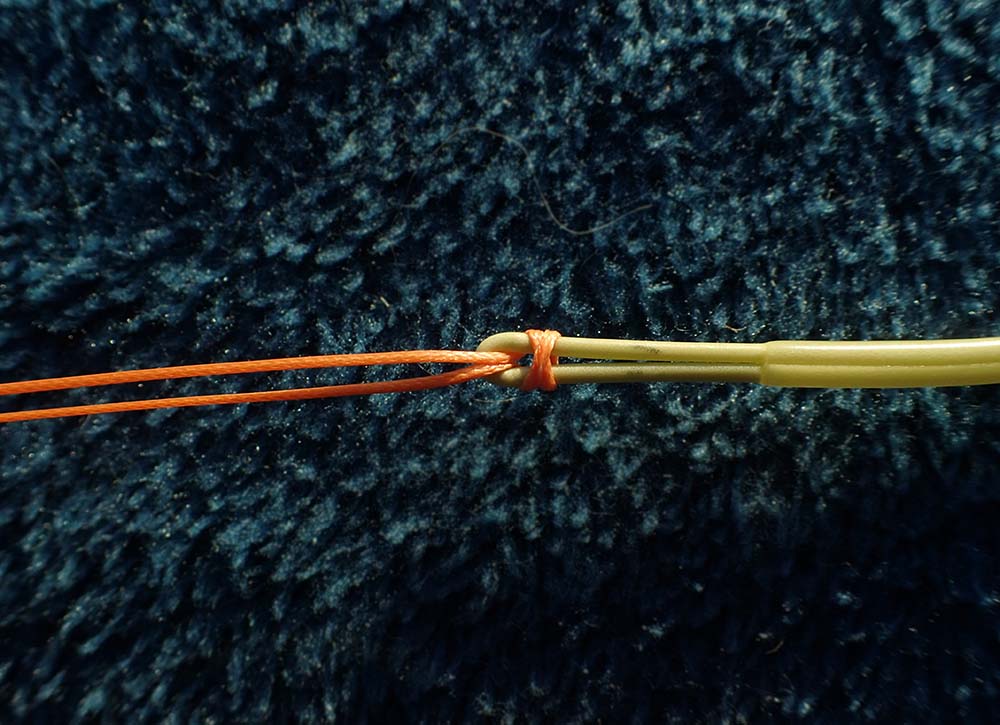

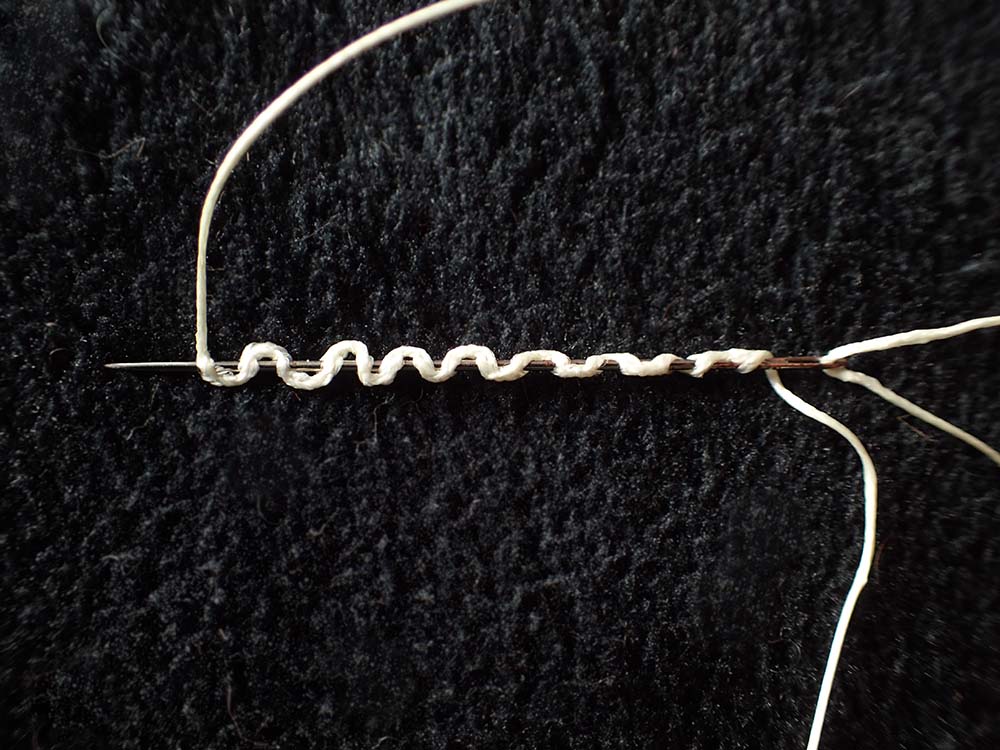

The Stitch Splice method is attributed to Shigeshi Tanaka and originally developed to create loops in braid to increase the strength of the connection to monofilament leaders on conventional gear. It involves using a regular needle to sew the tag end back into the mainline, using at least 14 stitches about 3-5mm apart. I like 25-30 stitches for backing loops.

I discovered the Stitch Splice method on sealine.co.nz from a posting by Reefman, which is reposted elsewhere online including the Biggame Fishing-Board. At the end of this article I provide a link to a PDF explaining this method.

The beginning of a Stitch Splice - the first 13 stitches on a needle. At this stage I usually pull the tagged through the stitches, adjust the loop size, and then do another 12 or so stitches

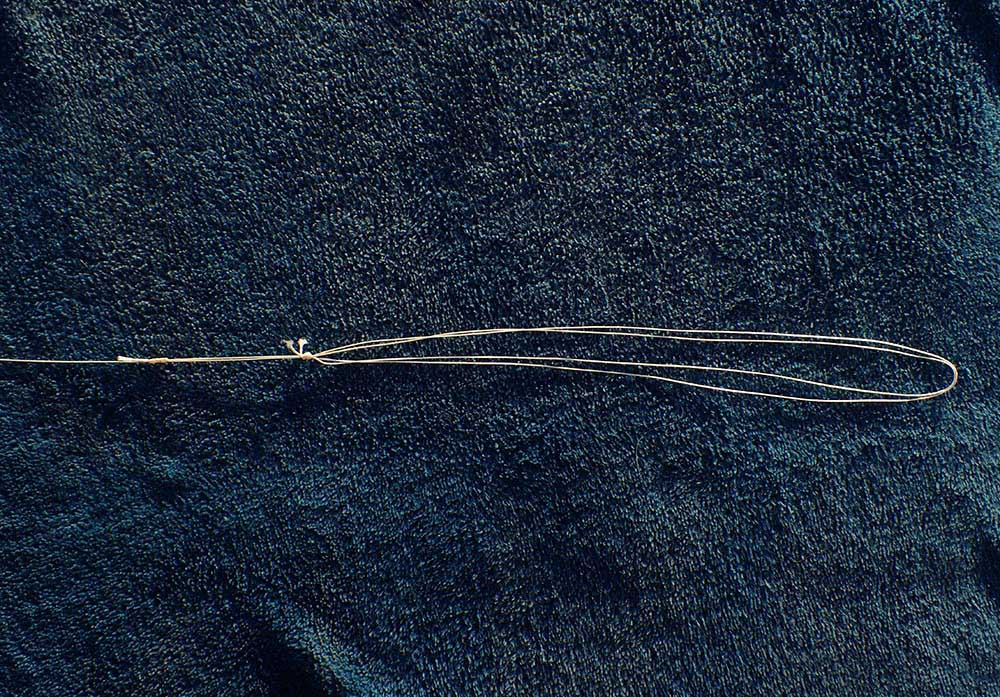

The Stitch Splice completed with 25 stitches in 0.38 mm 8 carrier braid. Note the tag end is not knotted

Apart from attaching fly lines, Stitch Spliced loops can also be used to join lengths of backing. Backing can either be joined loop-to-loop or by a double-stranded double uni-knot, essentially tying the loops together. This connection is not weaker than the full breaking strain of the thinnest braid being connected. Braid of different diameters is easily connected using this method.

Hollow Core Braid

The latest development in braid technology is 16 carrier hollow core braid. Although developed primarily for gamefish on conventional gear it has many attributes that make it a great fly line backing.

The advantages of hollow core braid for backing are:

• Being hollow and constructed from 16 bundles of threads, hollow core braid is more abrasion resistant than 8-carrier braid of the same breaking strain and also exceptionally smooth.

• It's easily spliced to join or make end loops, using well established methods and splicing tools, without compromising breaking strain.

• Since hollow braid packs down flat on the reel there’s theoretically less chance of it cutting into itself than with solid braid of the same breaking strain, especially if not retrieved evenly and/or under tension.

• Depending on the diameter of hollow core braid it can be spliced directly onto the fly line once the loop is removed, creating an extremely strong and ultra smooth connection. If you need to use another fly line on the spool, simply cut the backing off at a couple of feet behind the end of the fly line, then splice an end loop in the braid ‘tail’ for attaching to the reel in future.

• For the Spey angler, hollow braid can be spliced directly onto both mono and coated running lines provided the mono running line is thick enough. Thirty-five pound Scientific Anglers flat mono running line can be spliced directly into 60 lb hollow core, but 35lb OPST Lazar Line is too skinny.

Hollow-core fly reel backing recommendations are 40 lb (0.28 mm) for freshwater and light salt water (5-7wt), 60 lb (0.36 - 0.4 mm) for Spey and average salt water gamefish (8-10 wt) and 80 lb for heavy weights (11wt and above).

Hollow core is considerably more expensive than 8-carrier solid braid. When it comes to trout, I don’t believe 40 lb hollow core offers a practical advantage over a thin 50 lb 8-carrier braid with an abrasion resistant coating, e.g. Siglon ADV, especially if a Stitch Splice is used to create the loop.

The higher abrasion resistance and handleability of 60 lb hollow core is definitely worth considering for saltwater outfits.

Sixty pound hollow core braids commonly used for fly line backing include: Power Pro HollowAce, Seaguar Threadlock and Cortland C16.

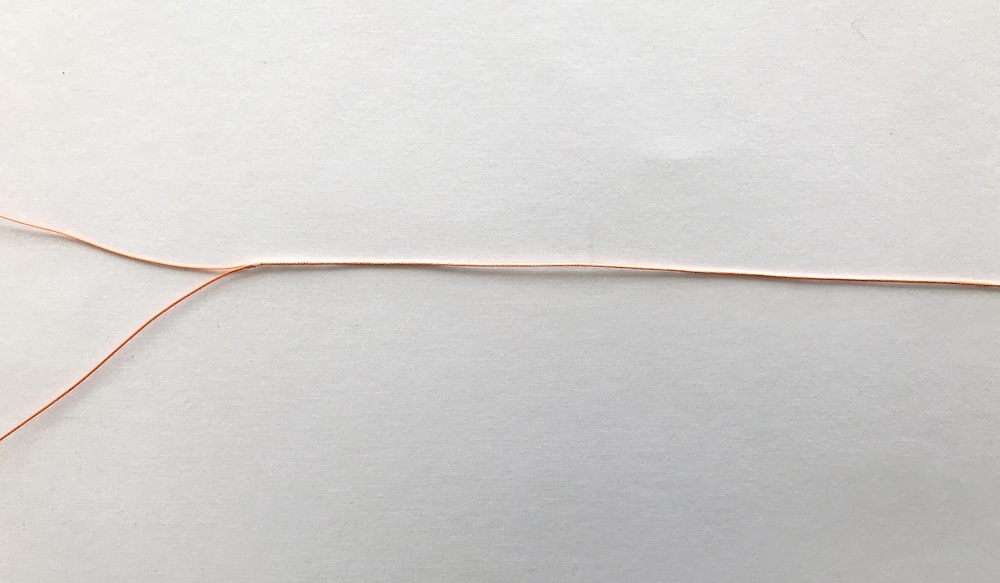

Daiwa J-Braid Hollow Core is a relatively new product, available in 60 lb, 80 lb and 100 lb, and since it’s readily available in New Zealand I was able to buy some to test.

J-braid hollow core is bright orange with a black band of around 30cm every 25 m, which is useful for spooling reels and gauging fish distance.

The 60 lb J-braid, the lightest in the series, is thinner than Scientific Anglers 20 lb Dacron, is incredibly smooth and it can be spliced onto the rear of a 9wt floating fly line. With a diameter 0.40 mm it is, however, a tad thicker than the standard 0.37mm 60 lb 8-carrier saltwater alternative.

I did some backing capacity comparisons with a Nautilus NV-G 8/9 reel and found that 175 m of 60 lb J-braid took up the same amount of space as 200 m of Hatch Outdoor backing. So you would fit 13% less 60 lb hollow core than 60 lb 8-carrier braid on a reel.

The 100 lb J-Braid hollow-core has similar diameter to Scientific Anglers 30 lb Dacron. My Hardy Perfect 3 7/8 inch Taupo reel is filled to the same level with 200m of either 30 lb SA Dacron or 100 lb Daiwa hollow-core.

The advantage of using braid on the Hardy is that it absorbs less water than Dacron so will dry quicker, which is relevant as the spool has very little porting to allow backing to dry. PE braid is also less prone to mould or rotting than Dacron.

It’s also worth noting that the Hardy was 0.75 ounces lighter with braid than when filled with the same length of Dacron as PE braid has a lower density than Dacron.

A loop created in hollow-core braid with a reverse blind splice

Combining solid braid with hollow core

The first 100m of saltwater backing sees more time out of the guides, is usually closest to snags on long runs and comes under strain when putting on pressure to land a fish.

If your saltwater fly reel wont take the required amount of 60 lb hollow braid, or you want to avoid the cost of filling the reel with hollow-core, then adding a top shot of 100 m of hollow core to a base of 50 lb solid braid may give you the capacity needed but with many of the benefits of hollow core.

If you’re tackling species that head for snags, eg giant trevally or yellow kingfish, you’re usually in trouble if you let them run more than about 25m, so the top shot gives you the power and abrasion resistance to hold on tight.

When you hook a clean fighting gamefish capable of running hundreds of meters, on the same outfit,the additional length of skinny solid braid provides the capacity required. The skinny solid braid also provides significantly less tippet popping drag when an oceanic speedster 200 plus meters out swims in an arc.

It’s possible to splice solid braid into hollow braid, however if the solid braid is thinner than the hollow braid an in-line finger trap splice wont work. A loop-to-loop connection, using a Stitch Splice in the solid braid and a reverse blind splice in the hollow core, produces a connection that wont compromise the breaking strain of either.

A twist on the top shot approach is to add 60 lb hollow core to 40 lb hollow core. Although there would be no cost saving with this option, the lines can be joined with an ultra smooth in-line splice, where a length of each braid type is spliced into the core of the other - see link below.

Both Cortland and Power Pro produce 40 lb hollow-core braid.

Tips for Purchasing braid

Whether you choose 8-carrier solid or hollow-core braid you do not need to purchase products marketed specifically for fly line backing. In fact, some products developed for conventional gear by top manufacturers of braid are arguably better - especially those with better breaking strain to diameter ratios and with slick, abrasion resistant coatings that penetrate between the fibres.

The most cost effective purchases of braid are often from bulk spools at a local conventional tackle dealer. They usually have a wide range of brands and breaking strains so you’re able to choose the diameter, coating and colour that suits you best. You can also purchase exactly how much you need.

If you choose to buy a large spool to fill multiple reels,the multi-coloured options will allow you to measure off specific lengths - it usually changes colour every 10m, with an additional mark every 5m. Daiwa J-braid hollow core has a short black band every 25 m, which is handy for this purpose.

Summing up

PE braid has come a long way in the last two decades and now has many advantages over Dacron as a fly line backing material: It is much thinner for a given breaking strain, it absorbs less water and is much more durable and impervious to the elements, including UV.

Unlike the original 4 strand PE braided lines, 8-carrier solid braid and 16-carrier hollow braid are silky smooth.

Eight carrier solid braid with a diameter around 0.37-0.38 mm has a good track record as fly line backing for both fresh and saltwater.

My choice of 8-carrier braid for fly-reel backing is Siglon ADV. It has an independently tested excellent breaking strain to diameter ratio and is impregnated with a proven water repellant and abrasion resistant coating that wont rub off.

I like the 0.34 mm 50 lb ADV for trout because it’s not overly skinny and I can fit 100 m of it on several reels of mine that will take only 75 m of 0.37 mm braid with a 5wt floating line. The 0.38 mm 60 lb ADV is great for large arbor saltwater and Spey reels that have limited backing capacity.

Sixteen strand hollow core PE braid is growing in popularity as fly line backing.

The main advantage of hollow core is that it’s more abrasion resistant than solid braid, is easy to splice joins and end loops with well established techniques. It can also be spliced directly onto fly lines to create an extremely strong and ultra-smooth connection.

The primary disadvantage of hollow core is that it’s much more expensive than 8 ply solid braid.

While hollow core may be overkill for trout, it’s definitely worth considering for salt water applications where hard fighting gamefish are expected to make long runs in rough terrain, as well as for species that need to be bullied around structure.

Sixty pound Daiwa J-Braid Hollow core makes an excellent saltwater fly line backing.

A potential drawback is that it is slightly thicker than 60 lb 8-carrier solid braid and you will fit around 13% less 60 lb hollow-core on your reel.

If your large arbor salt water fly reel wont hold enough 60 lb hollow core, adding a top shot of 100 m 60 lb hollow core to a base of 8-carrier solid braid will provide many of the advantages of hollow core but with greater backing capacity. The first 100m of backing usually experiences more use and abuse than the remaining backing. This approach allows you to use a thinner gauge 8-carrier braid for the base, e.g. Siglon ADV 50 lb, to maximise backing capacity.

Well that’s it.

I hope this article provides the information needed when making decisions about backing for your favourite fly reel.

Links

Youtube video : Reversing blind splice in hollow core using wire

Youtube video : Joining hollow core braid

This splice can also be done with piano wire.

You need to come in from the opposite direction than the loop needle, as you are pushing in the loop rather than the point.

Youtube video : Splicing Hollow Core directly to fly line

See other reviews :